HPX hot air circulation drying oven

Equipment introduced

1) principle

A, a total of 7 side-by-side conveyor belt, adjacent to the opposite direction of movement; bottle from a conveyor belt forward movement to reach the end, under the action of a ramp, the transition to another, the reverse movement, so , The bottle is transported back and forth on the conveyor and delivered from the last conveyor.

B, each conveyor belt just above a row of air outlet, air outlet is on the conveyor belt movement bottle.

C, the fan sucked in the air below the box, and then through a row of heating pipe, take out the heat from the top of the bottle outlet, the bottle drying; after the bottle of air and then by the fan inhalation, so cycle.

D, thermostat control: thermocouple in the heating box, when the detected temperature on the thermocouple reaches the set value, the heating tube stops heating, when the temperature is lower than the set value, the heating tube resumes heating.

2) The main technical parameters

Bottle specifications: 50ml (φ35 × 108mm); 100ml (φ46 × 120mm)

250ml (φ62 × 145mm); 500ml (φ80 × 180mm)

Baking time: 120 seconds (bottle into the box to the time out of the box)

Theoretical capacity (drying time 120 seconds, temperature 180 ℃ conditions):

68,000 bottles / 4 hours (50ml time); 40000 bottles / 4 hours (100ml time)

20000 bottles / 4 hours (250ml time); 10000 bottles / 4 hours (500ml time)

Temperature adjustment range: 120 ~ 180 ℃

Heating method: hot air circulation

Conveyor belt number: 7

Moisture volume: 200 ~ 500m3 / h

Wind pressure: ≥200Pa

Power: 380V 50Hz / 60Hz three-phase five-wire system

Power: ≤ 30Kw

Overall dimensions: 3500 × 900 × 2200

3) The main components of the device configuration

No. | Name | Model or material | suppliers |

1 | PLC | FX3U-30MT | Japan Mitsubishi |

2 | touch screen | GS2107 | Japan Mitsubishi |

3 | Inverter | FR-A740-0.75K | Japan Mitsubishi |

4 | thermocouple | E52-CA15AY | Japan Omron |

5 | temperature controller | E5EZ-R3T | Japan Omron |

6 | SCR | KS50A | Shanghai |

7 | low noise centrifugal fan |

| Jiangsu HONGDA |

8 | high temperature fan | stainless steel | NANJING |

9 | other electrical components |

| France Schneider |

10 | bottles conveying system | components | Nantong Bo Lang |

11 | hot air circulation system | components | Nantong Bo Lang |

12 | heating system | components | Nantong Bo Lang |

13 | transmission | components | Nantong Bo Lang |

14 | Rack | Assembly (A3) | Nantong Bo Lang |

15 | edge board | components (304 #) | Nantong Bo Lang |

4) the main components of material

High temperature tank liner: 2mm heat-resistant acid-resistant stainless steel

Cabinet shell: 304 # stainless steel

Outsourcing board: 304 # stainless steel

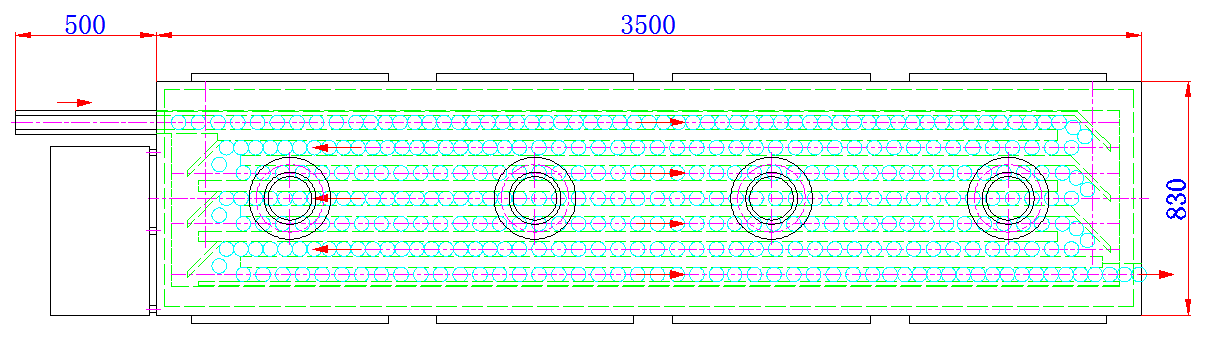

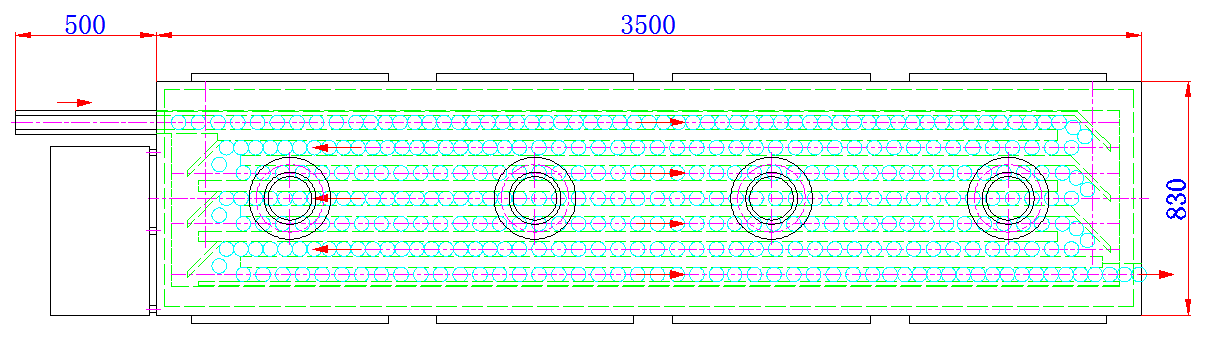

Equipment plane schematic