Equipment introduction

一GP1000 type bottle feed turntable

1 Introduction

This machine is an auxiliary machine for the production of plastic bottles or glass bottles for liquid filling production line. It has the functions of bottle storage and bottle handling.

2) The main technical parameters

Production capacity: to meet production needs

Turntable diameter: φ800mm

Source: 220V 50Hz

Power: 0.2Kw

Dimensions: 1000×1000×1200mm

3) Main device component configuration

Gear Reducer Motor Manufacturer: JINWEIDA Motor

4) Material of main parts

Outsourcing board: 304# stainless steel

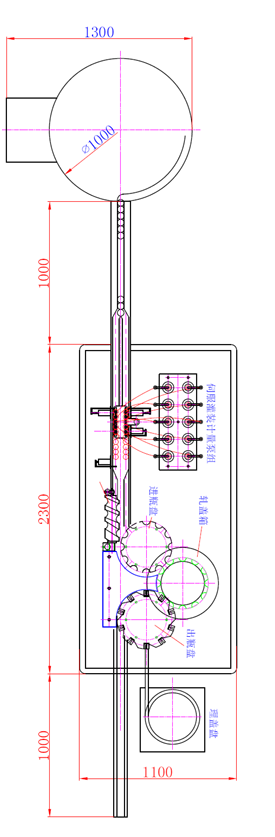

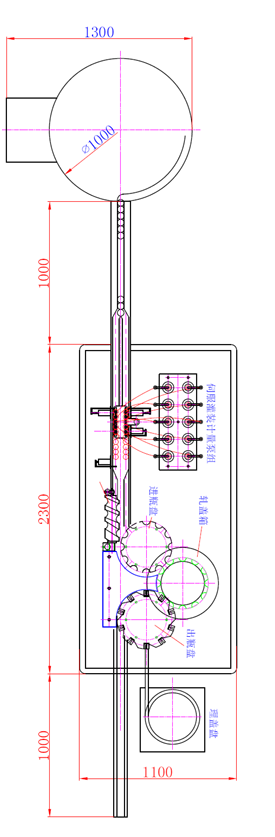

二YGF10/10 spray bottle filling capping machine

Picture for reference only

1) Use and introduction

This equipment is the main filling machine in the spray bottle liquid filling production line. It is mainly used for filling, capping and screw cap sealing of 30ml straight tube bottles. The filling is completed by a ten-head plunger pump, servo metering, accurate filling, linear servo filling on the conveyor belt, realizing the function of no bottle no filling; the capping adopts ten-head manipulator planetary tracking capping, automatic cap supply and The cap is worn by a manipulator, and the action is reliable; the screw cap has a constant torque to ensure that the appearance of the cap is not damaged. The machine combines filling and sealing into one, with advanced design and compact structure.

2) Main technical parameters

Production capacity: 100-120 bottles / miute

Applicable specifications: spray bottle

Number of filling heads: ten head

Filling form: Servo-controlled plunger pump

Loading error: 0~2%

Capping type: Screw capping

Number of capping heads: ten head

Power source: 220V/380V 50Hz/60Hz

Power: 3Kw

Dimensions: 2200× 1300 × 1850MM

4) Main device component configuration

No. | Name | Model or material | suppliers |

1 | PLC | DVP14SS11T2 | Taiwan delta |

2 | touch screen | DOP-B05S100 | Taiwan delta |

3 | Inverter | FR-A740-0.75K-C | Taiwan delta |

4 | pneumatic components |

| Taiwan AIRTAC |

5 | sensor | BW200-DDT | Korea Autonics |

6 | Plunger pump |

| Beijing |

7 | high-precision dividing box | RTT80-12-2: 1 | Zhucheng Mingxin |

8 | Spray pump unscrambler | 500 (304 #) | Shanghai Dinghua |

9 | other electrical components |

| France Schneider |

10 | Equal parts | nylon | Nantong Bo Lang |

11 | bottles system | components | Nantong Bo Lang |

12 | Filling system | components | Nantong Bo Lang |

13 | Spray pump stacker system | components | Nantong Bo Lang |

14 | Outer cover feeding system | components | Nantong Bo Lang |

15 | screwing system | components | Nantong Bo Lang |

16 | transmission | components | Nantong Bo Lang |

17 | rack, platen | assembly (A3) | Nantong Bo Lang |

18 | side panels, panel | components (304 #) | Nantong Bo Lang |

5) Main component materials

Metering part: 316# stainless steel

Other parts in contact with the bottle: 304# stainless steel and nylon